Characteristics of steel

This alloy is one of the hot work, chromium type tool steels. It also contains molybdenum and vanadium as strengthening agents. The chromium content assists this alloy to resist softening if used at higher temperatures. Secondary hardening steels with good tempering reistance. It maintains high hardness and strength at elevated temperatures. Good resistance to thermal fatigue, erosion and wear. Steel with very high thoughness and good ductilityand hardenability. Tools can be water cooled. Compared to 1.2343, it is more resistant to the formation of cracks after thermal stress with low sensitivity to sudden changes in temperature. This steel can be produced also as ESU, or ESR, means electroslag remelted steel with high structure purity for highly stressed forms.

Suitability of steel use

This steel finds applications for hot die work, die casting and extrusion dies, wear resisting tools, pressure die casting tools, pressing tools for light and heavy metal. For the highest requirements we recommended 1.2344 ESR.

Downloads

Chemical composition of steel

| Jakost oceli | C | Mn | Si | Cr | W | Mo | V | Ni | P | Co | S |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DIN / EN X50CrVMo51 | 0,37-0,43 | 0,30-0,50 | 0,90-1,20 | 4,80-5,50 | 1,20-1,50 | 0,90-1,10 | 0,035max. | 0,035 max. |

|||

| ČSN 19554 | 0,34-0,44 | 0,20-0,50 | 0,80-1,20 | 4,80-5,80 | 1,10-1,60 | 0,80-1,20 | 0,030 max. | 0,030 max. |

Steel hardness

| Tepelné zpracování | HB | HRC | Stav dodání |

|---|---|---|---|

| Žíháno na měkko | max. 235 | A | |

| Zušlechtěno | min. 51 |

Heat treatment

Následně nechat ochlazovat v popelu, velké bloky / průměry pozvolna v peci

Prohřát a následně pomalu ochlazovat v peci.

Prohřátí, 1-2 hod. podržet. Následně pomalu vychladnout v peci

Postupné ochlazovat v oleji nebo v horké lázni , vakuum, inertní plyn

Ochlazovat na vzduchu, popouštění se řídí dle popouštěcího diagramu / dle tabulky popouštěcích hodnot

Tempering values depending on hardness

| °C | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

|---|---|---|---|---|---|---|---|

| HRC | 53 | 52 | 52 | 52 | 54 | 48 | 31 |

| N/mm2 | 1845 | 1790 | 1730 | 1790 | 1910 | 1680 | 995 |

Supply options

Choose from a range of steels. Other dimensions on request, from central stock or new production.

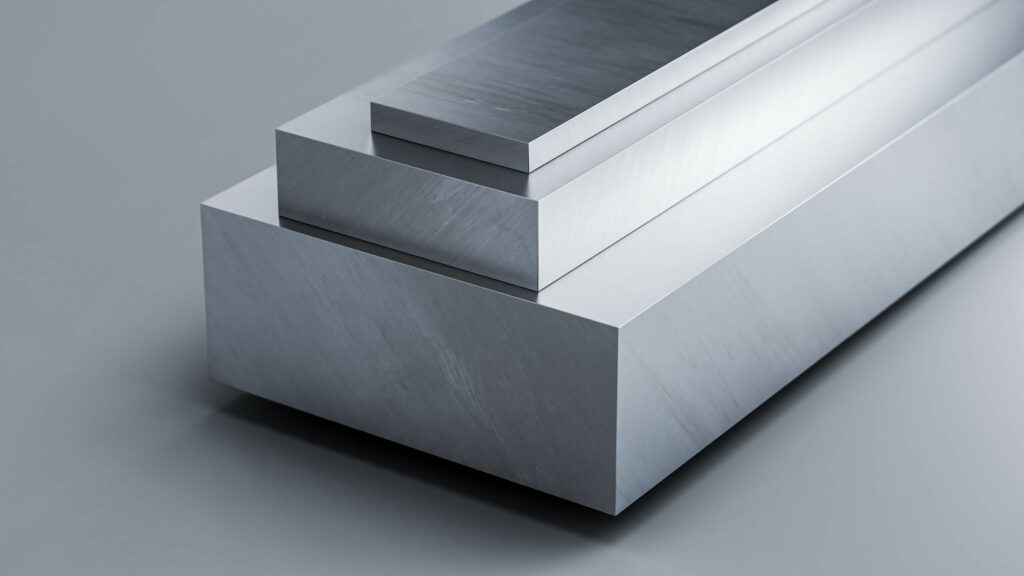

Block

Forged, For hot work.

| W.nr | 1.2344 |

|---|---|

| ČSN | 19 554 |

| DIN-EN | X40CrMoV5-1 |

| Stav dodání | +A / ESR |