Characteristics of steel

This material is 5% chromium hot work tool steel designed particularly for applications requiring extreme toughness combined with good red hardness. It provides an extra margin of safest in tools subject to heavy hammer blows, and those tools containing deep recesses or sharp corners. While is has been designed primarily as a hot work tool steel, it has been used in many cold work applications where extra toughness is required at the sacrifice of some wear resistance.

Suitability of steel use

It has been used primarily for tools requiring resistance to softening at elevated temperatures. Such tools include forging dies and punches, die-casting dies, aluminium extrusion dies, hot heading dies, piercing and forming punches, etc.

Downloads

Chemical composition of steel

| Jakost oceli | C | Mn | Si | Cr | W | Mo | V | Ni | P | Co | S |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DIN / EN X50CrVMo51 | 0,4-0,51 | 0,29-0,31 | 0,75-0,95 | 4,80-5,50 | 0,90 | 0,035max. | 0,035 max. |

Steel hardness

| Tepelné zpracování | HB | HRC | Stav dodání |

|---|---|---|---|

| Žíháno na měkko | max. 240 | A | |

| Zušlechtěno | min. 56 |

Heat treatment

Následně nechat ochlazovat v popelu, velké bloky / průměry pozvolna v peci

Prohřát a následně pomalu ochlazovat v peci.

kalit lze i na vzduchu, v teplé lázni

Ochlazovat na vzduchu, popouštění se řídí dle popouštěcího diagramu / dle tabulky popouštěcích hodnot

Tempering values depending on hardness

| °C | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

|---|---|---|---|---|---|---|---|

| HRC | 63 | 62 | 59 | 57 | 57 | 51 | 36 |

| N/mm2 | - | - | - | - | - | - | - |

Supply options

Choose from a range of steels. Other dimensions on request, from central stock or new production.

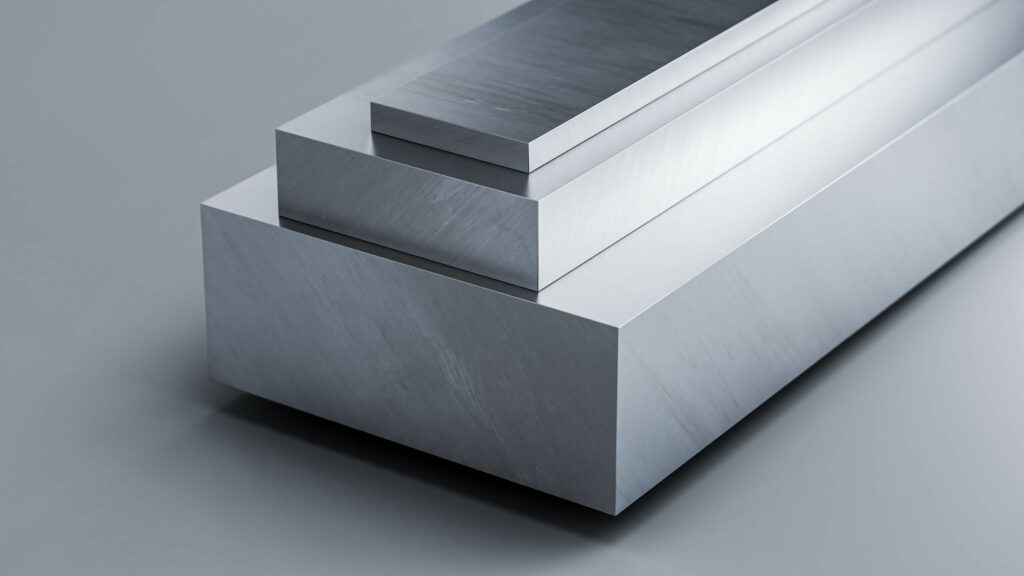

Block

Forged, For hot work.

| W.nr | 1.2345 |

|---|---|

| ČSN | - |

| DIN-EN | X50CrVMo51 |

| Stav dodání | +A |